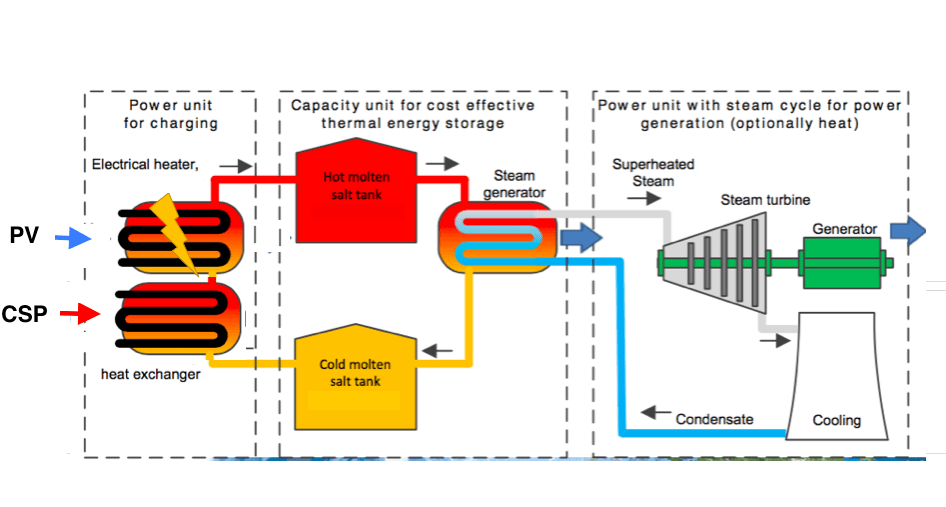

Utilize a tes tank to increase plant uptime and allow for more regular equipment maintenance thus increasing cooling system longevity and efficiency.

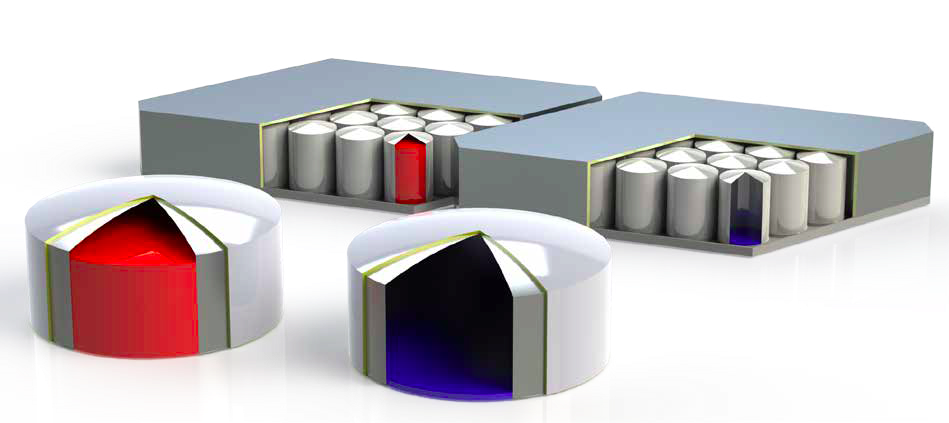

Thermal energy storage tank sizing.

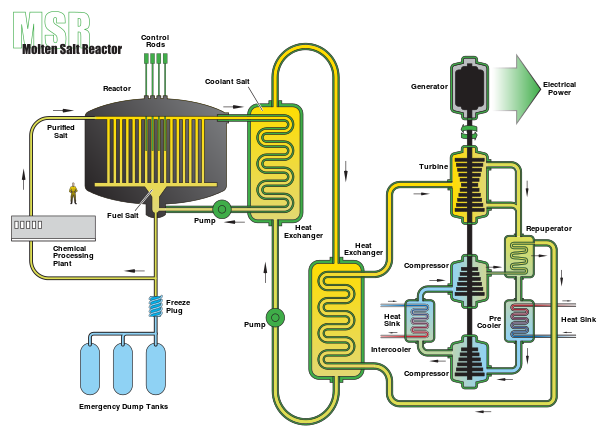

The adsorption cycle has already been used in several research projects to promote tes.

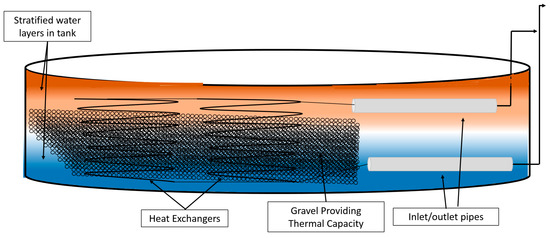

The system can be used as an air heating device or combined with a hot water tank.

Thermal energy storage tank discharge efficiency as a function of boiler nominal capacity and the amount of building heat demand.

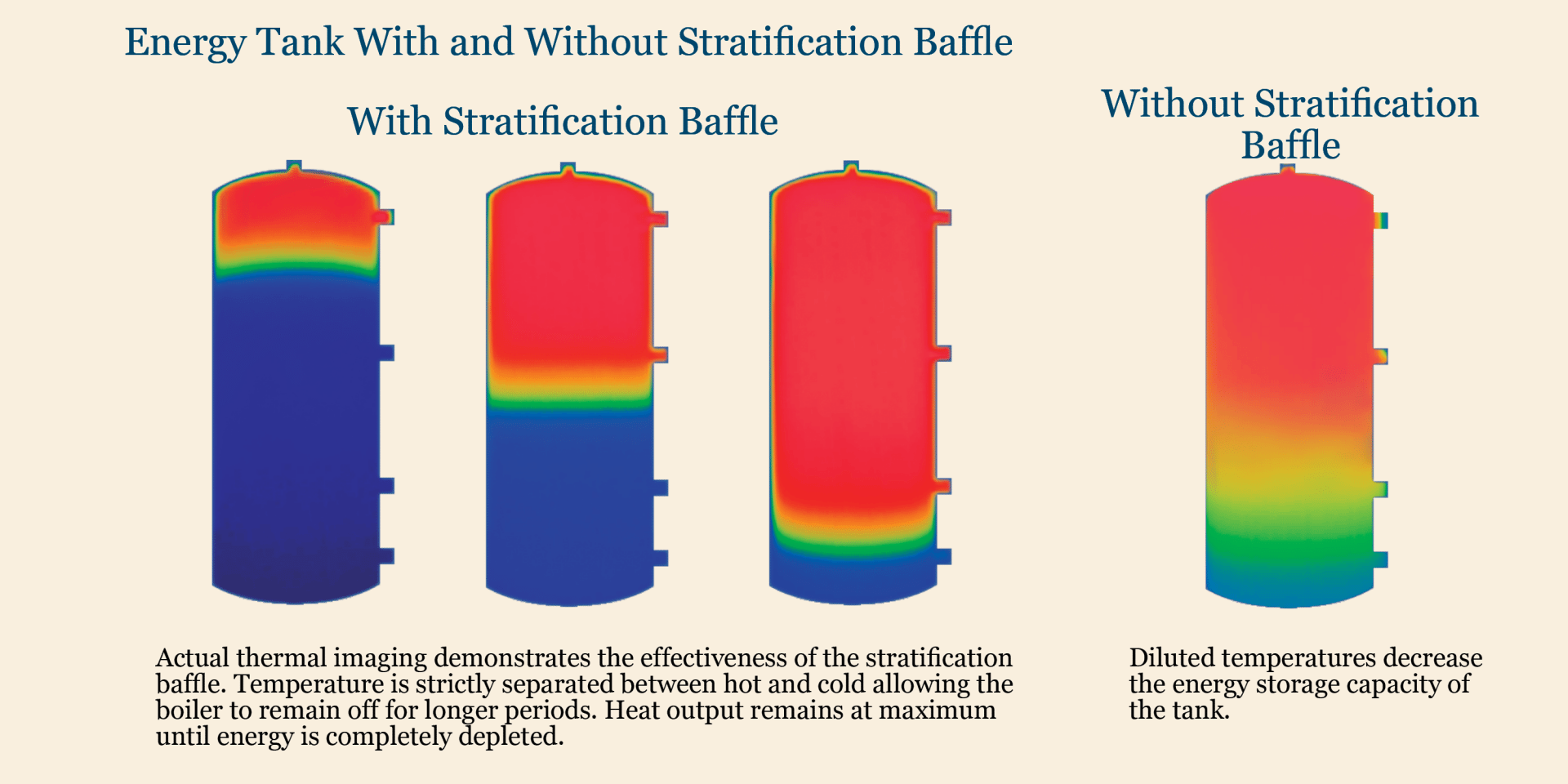

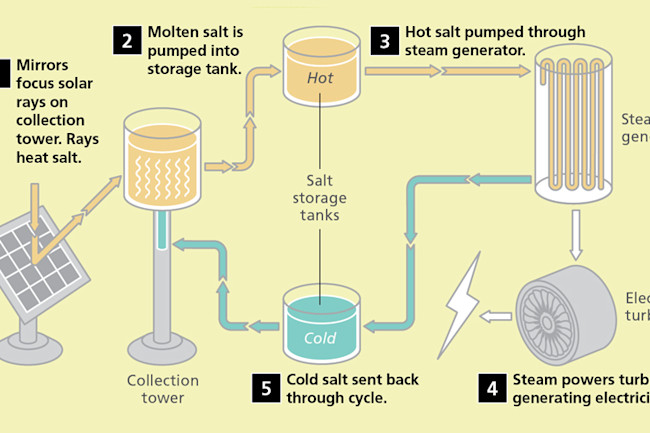

Thermal energy chilled water or hot water is produced during periods of off peak electrical demand or usage collected in a thermal energy storage tank then withdrawn and distributed to the facility during on peak periods.

Utilize a concrete thermal energy storage tank to meet increased cooling loads and avoid the capital expense of adding a new chiller cooling tower and pumps.

Usage examples are the balancing of energy demand between daytime and nighttime storing summer.

Thermal energy storage tes thermal energy storage commercialized over 30 years ago thousands of installations throughout the gcc world and the u s.

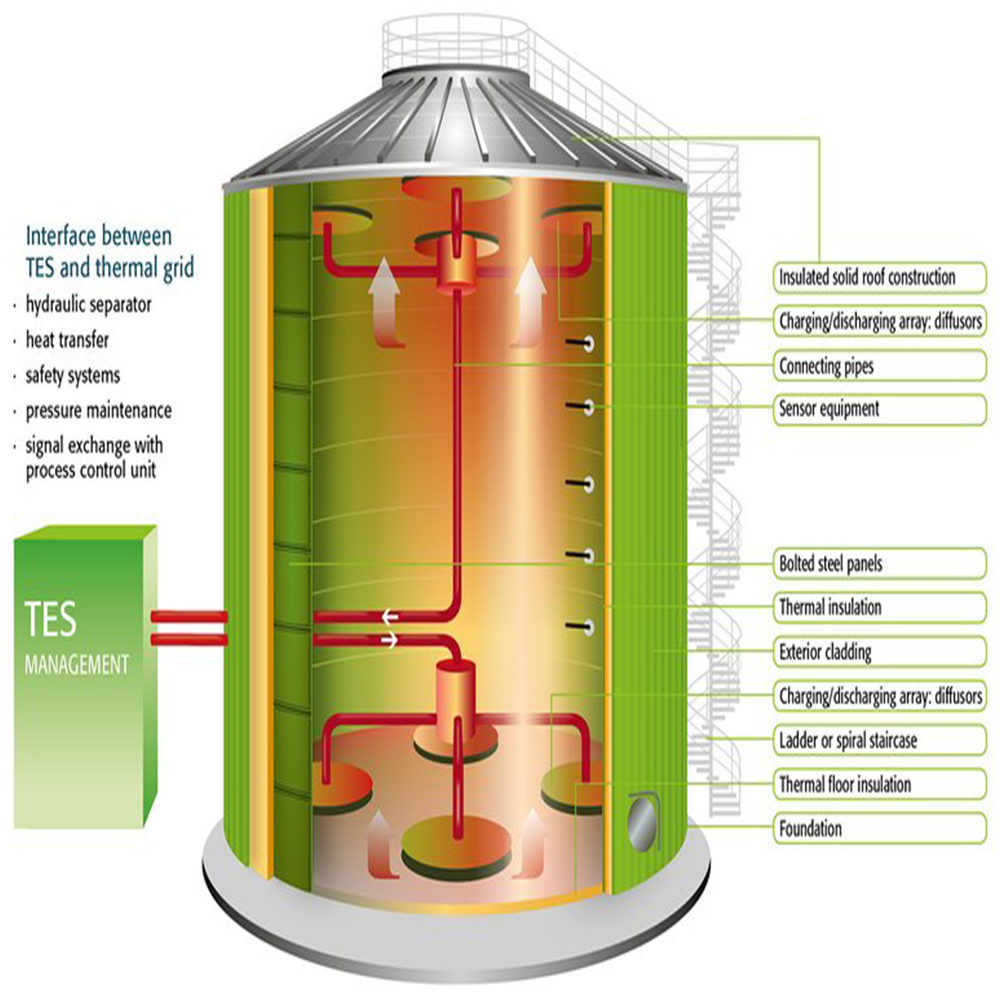

Our services include in house engineering design fabrication and erection of the foundation tank internal diffuser system and exterior insulation.

The discharge efficiency was the optimized storage tank discharge efficiency for different boiler nominal capacity n.

Thermal energy storage tank overview micah j.

Proper study of the tes system including plants details components system size operating patterns temperatures demand needs and more.

In 1990 kaubek and maier laxhuber 56 patented an adsorption apparatus to be used as an electric heating storage working with the zeolite water pair and reporting a 30 savings in the energy consumption.

Selection of the optimal tes technology in accordance with the client s requirements whether it be a naturally stratified chilled water tank ice storage or other thermal energy storage method.